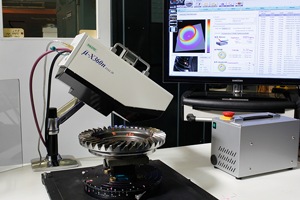

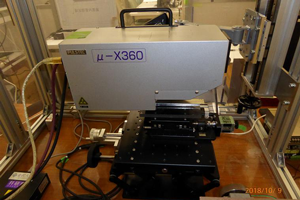

µ-X360 Portable X-ray Residual Stress Analyzer

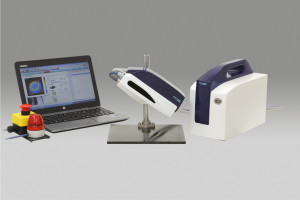

Added new model ‘μ-X360s’ that is the world’s lightest and smallest residual stress analyzer.

This is non-destructive measurement system for residual stress, retained austenite, FWHM based on X-ray diffraction technique, and excellent for portability, reliablity, safety, operability, cost and etc.

Features

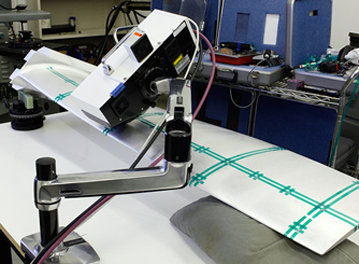

Portability

- The world’s lightest and smallest

- Able to measure in pipes with internal diameters down to 170mm wide

- Easy to carry anywhere

Safety

- Low operational power 30KV & 1.5mA

- Scattered X-ray radiation is same level as nature level when 3 meters away from the sensor unit. (in use with standard collimator)

- Simple air cooling system

Reliability

- Reliable measurement by cos α method

- Easy position setting by single incident angle measurement

- Detecting 500 points data from the complete Debye ring

- High repeatability

X-Ray tube exchange

- Possible to exchange the tube by customer. 5 types of X-ray tubes, ‘Cr, V, Cu, Co, and Mn’ are available

Operability

- Easy operation

- Easy sample positioning

Certification of standard

- CE marking

Measurement speed

- 60 secs / measurement point

Application

- Plastic forming. (Rolling, pressing, molding)

- Thermal treatment. (Quenching, annealing, sub-zero treatment)

- Surface reformation. (Shot peening, shot blasting, laser shot peening)

- Domestic/Overseas universities and public research institutions

- Process improvements, quality control, yield improvement, equipment durability check, remaining life assessment of infrastructure, etc.

Demonstration video

- Metallic processing. (Welding, cutting, grinding)

- Maintenance of plant and infrastructure. (Stress corrosion cracking, monitoring

aging effects)